Why Co-Packaged Optics Uses External Lasers Instead of Integrated Sources

Deep Dives

Explore related topics with these Wikipedia articles, rewritten for enjoyable reading:

-

Distributed-feedback laser

1 min read

The article repeatedly references InP DFB lasers as the core technology for CPO systems, explaining their temperature sensitivity and wavelength characteristics. Understanding DFB laser physics would deepen comprehension of why external lasers are necessary.

-

Wavelength-division multiplexing

11 min read

The article explains how wavelength drift causes 'channel interference and data errors' in WDM systems. Understanding how WDM packs multiple optical channels together illuminates why 0.1nm/°C wavelength shifts are problematic.

-

Arrhenius equation

12 min read

The article states laser degradation 'follows Arrhenius-type relationships where device life decreases exponentially as temperature rises.' Understanding this fundamental rate equation from chemistry explains the physics behind temperature-dependent failure rates.

Welcome to a 🔒 subscriber-only deep-dive edition 🔒 of my weekly newsletter. Each week, I help investors, professionals and students stay up-to-date on complex topics, and navigate the semiconductor industry.

If you’re new, start here. See here for all the benefits of upgrading your subscription tier!

As a paid subscriber, you will also have access to a video explanation of this post, an executive summary with key highlights, and a google drive link to this article so that you can parse it with your favorite LLM to mine insights best suited to your needs.

CPO is not a new idea, and has been around for the last decade. I recommend Asianometry: The AI Bandwidth Wall & Co-Packaged Optics, if you are unfamiliar with the basic concept. For a long time, CPO has had to deal with challenges that involved laser integration.

The core problem is thermal. Modern switch ASICs dissipate hundreds of watts of power. Laser sources require precise temperature control to maintain stable wavelength, output power, and reasonable lifetimes. Placing these temperature-sensitive components directly adjacent to high-power switch silicon creates a fundamental conflict.

The second challenge is reliability and serviceability. Field data from hyperscalers shows that laser sources are among the top three failure modes in optical systems. In traditional pluggable transceivers, a failed laser means swapping out a front-panel module. In co-packaged optics, the laser is integrated with the switch ASIC itself. A laser failure would require replacing the entire package, an expensive and disruptive operation that undermines the business case for CPO deployment.

The industry’s solution to both problems is external lasers. By relocating laser sources away from the switch ASIC to front-panel modules, CPO systems can maintain lasers at controlled temperatures while preserving hot-swap serviceability. This approach, standardized through External Laser Small Form-Factor Pluggable (ELSFP) specifications, has become the practical path forward for CPO deployment.

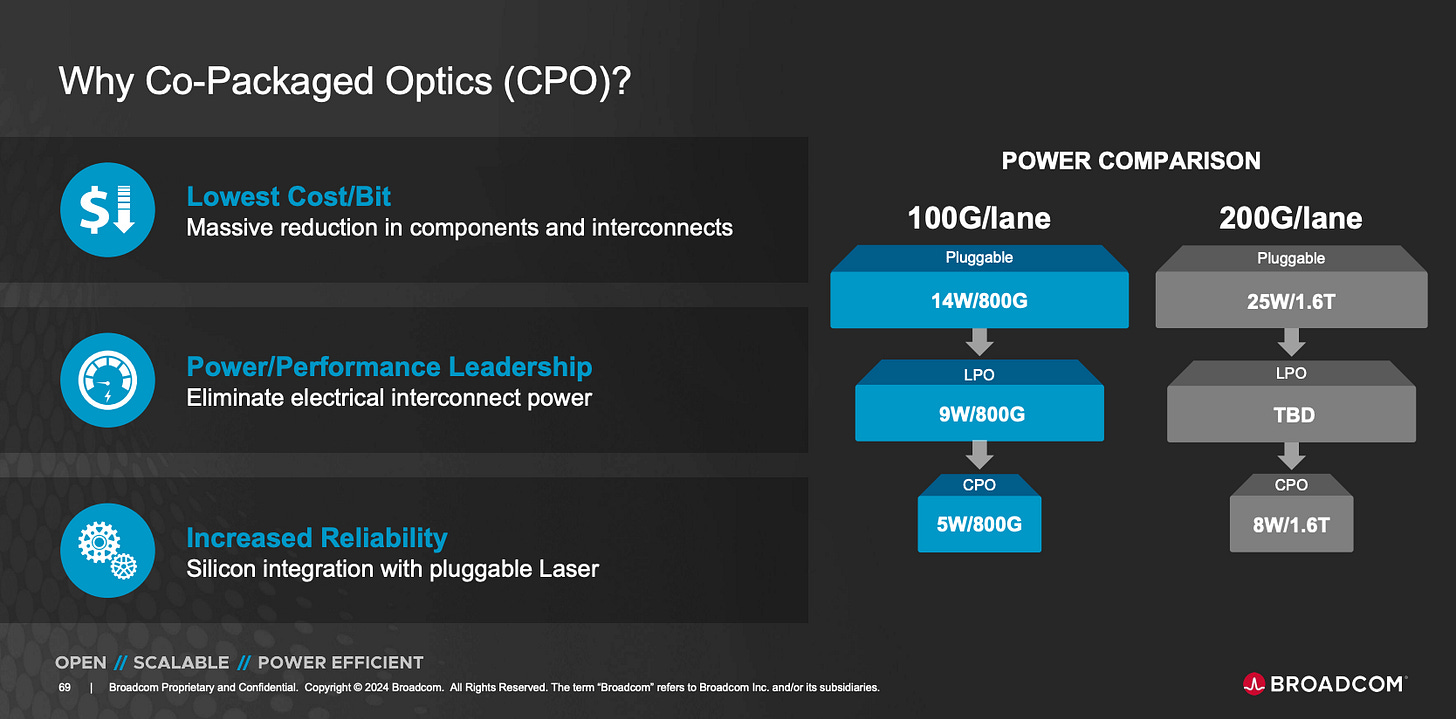

Today, CPO is a reality and it is not just speed that is a benefit; even at 800G interconnect speeds (100G/lane), there are significant energy savings. As speeds go to 1.6T and beyond, CPO becomes the primary technology of choice.

In this post, we will dig deeper into how external lasers solve CPO’s thermal and reliability challenges. We will cover:

Where to put the laser?: The architectural tradeoffs between traditional pluggable transceivers and co-packaged optics

Temperature Sensitivity in III-V Laser Wavelength: Why

This excerpt is provided for preview purposes. Full article content is available on the original publication.