What Is A Production Process?

Deep Dives

Explore related topics with these Wikipedia articles, rewritten for enjoyable reading:

-

Leblanc process

11 min read

Directly mentioned in the article as the process for refining potassium carbonate. This 18th-century industrial chemistry process was foundational to the chemical industry and exemplifies the interconnected production processes the article discusses.

-

Scientific management

11 min read

Explicitly referenced in the article as the early 20th century movement that studied worker motions. Frederick Taylor's scientific management revolutionized manufacturing efficiency and directly relates to the article's core theme of production process optimization.

-

Corning Inc.

14 min read

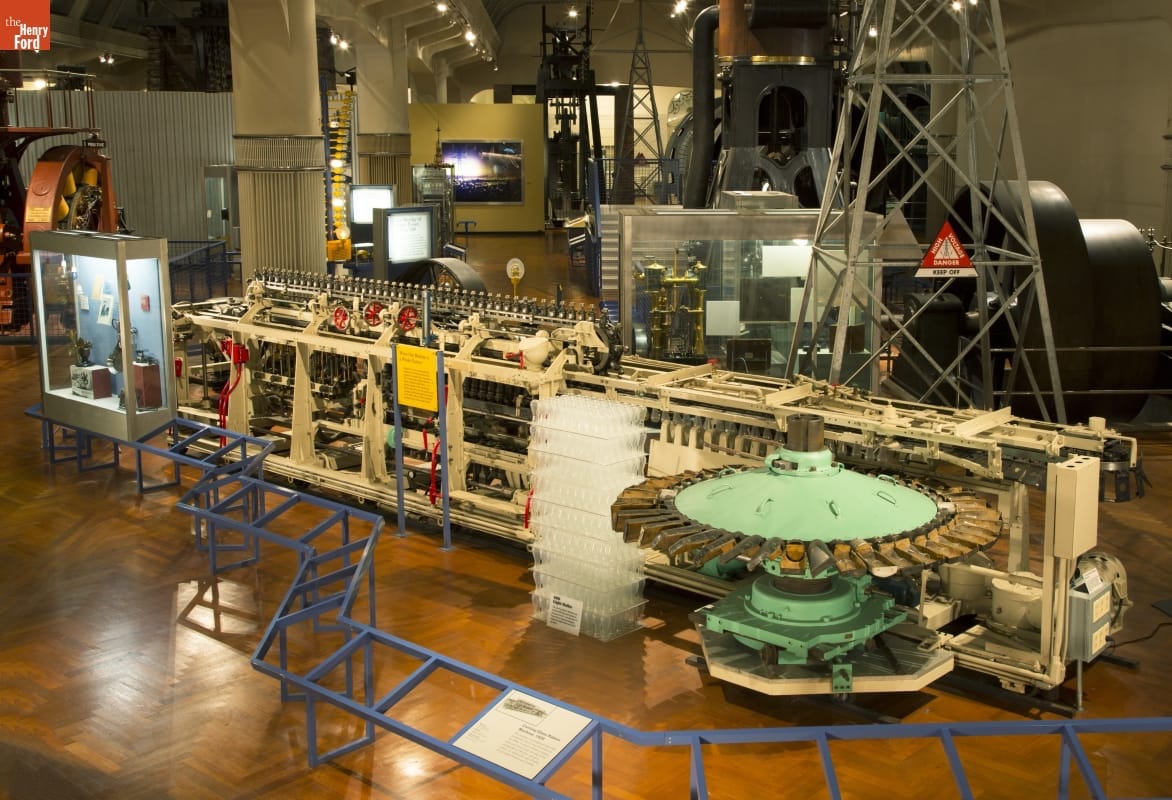

Central to the article's narrative as Edison's supplier of bulb blanks. The company's history of glass innovation, including the ribbon machine shown in the article's image, provides rich context for understanding industrial glass production evolution.

Below is the first chapter of my book, The Origins of Efficiency, available now on Amazon, Barnes and Noble, and Bookshop.

In 1880, Thomas Edison was awarded a patent for his electric incandescent light bulb, marking the beginning of the age of electricity. Although it was the result of thousands of hours of research that took place over decades by Edison and his many predecessors, the ultimate design of Edison’s light bulb was simple, consisting of just a few components: a filament, a thin glass tube in which the filament was mounted, a pair of lead-in wires, a base, and the glass bulb itself.

Until the 20th century, light bulbs were largely manufactured by hand. Workers would run the lead-in wires through the inner glass tube, attach the filament to the lead-in wires, and attach the glass tube to the bulb. A vacuum pump would then suck the air out of the bulb. Initially, this was done by connecting the pump to the top of the bulb, leaving a small tip of glass that had to be cut off. Later, tipless bulbs were developed that had the air removed from the bottom.

Most of this manufacturing process was done in house by Edison’s Electric Light Company, but the production of the glass bulb itself, known as a bulb blank, was outsourced. Edison placed his first order for bulb blanks with the Corning Glass Works company in 1880. The process of making the bulb blanks was fairly straightforward: Glassworkers would mix together sand, lead, and potassium carbonate, along with small quantities of niter, arsenic, and manganese oxide, place the mixture in a crucible, and melt it in a furnace into liquid glass. A worker called a gaffer would then gather a blob of glass on the end of a hollow iron tube and place the blob into a mold the shape of a light bulb. While the blob was still attached to the iron tube, the gaffer would blow into it to form the body of the bulb, then open the mold and cut the bulb from the end of the tube.

We can draw this series of steps using a process flow diagram, a visual representation of how a process unfolds. See Figure 2 for an example of what the bulb blank process might look like. Making bulb blanks

...This excerpt is provided for preview purposes. Full article content is available on the original publication.