TSMC Overseas Fabs – A Success?

Deep Dives

Explore related topics with these Wikipedia articles, rewritten for enjoyable reading:

-

Morris Chang

15 min read

The article frequently references Dr. Morris Chang as TSMC's legendary founder whose views shape the company's strategy. Understanding his biography, his founding of TSMC, and his philosophy on semiconductor manufacturing provides essential context for his skepticism about overseas fabs.

-

Hsinchu Science Park

13 min read

The article specifically mentions Hsinchu Science Park as 'the semiconductor epicenter of the world' and discusses the 'clustering effect' that makes it successful. Understanding how this industrial park developed and why clustering works there illuminates why replicating it in Arizona is so challenging.

-

CHIPS and Science Act

15 min read

The article discusses U.S. government efforts to onshore semiconductor manufacturing and subsidies of 'tens of billions of dollars.' The CHIPS Act is the specific legislation driving TSMC's Arizona investment, and understanding its provisions and goals provides crucial policy context.

Earlier this year, U.S. President Donald Trump called TSMC “one of the most important businesses in the world.” Although he was incorrect, TSMC is the most important business in the world, his government and others do realize the importance of bringing TSMC into their countries.

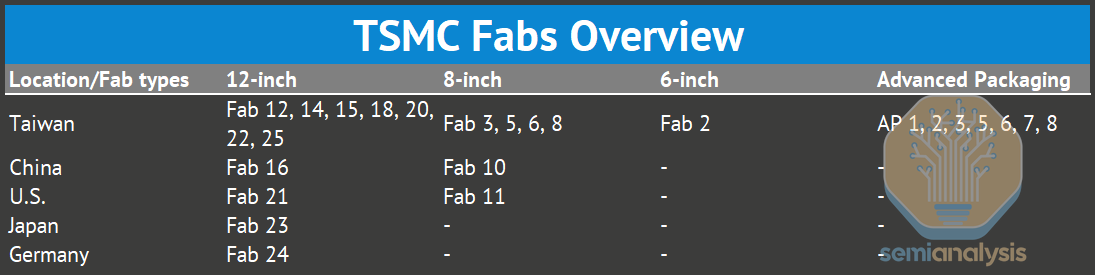

This drive to on-shore advanced semiconductor manufacturing has spawned three TSMC overseas ventures: in the United States, Japan, and Germany.

Five years on, these projects are all yielding wafers. But at what cost? Have both TSMC (and by extension, Taiwan) and these foreign countries achieved their goals? Are the overseas fabs economically competitive? Dr. Morris Chang, the company’s legendary founder, has been pessimistic on the U.S. fabs (emphasis added):

…We think that the recent effort of the U.S. to increase onshore manufacturing of semiconductors, right now you’re talking about spending only tens of billions of dollars of money of subsidy. Well, it’s not going to be enough. I think it will be a very expensive exercise in futility

With the fabs operating in high volume, we can finally answer all of that and more in this report. First, some details on what makes TSMC successful, including their history, culture, and structure. Next a discussion of the “clustering” effect that makes Hsinchu Science Park the semiconductor epicenter of the world, and Arizona’s progress towards replicating it, including a detailed look at the supply chains in both places. Finally, we’ll detail the economics of the TSMC Arizona fab - is it truly more expensive to make wafers in the U.S.?

Taiwanese Roots

TSMC operates as a global leader in semiconductor manufacturing, collaborating with hundreds of international clients. Yet, unlike many multinational corporations, it remains deeply Taiwanese at its core, with operations and talent overwhelmingly concentrated on the island.

Of TSMC’s 83,000+ global employees, close to 90% are Taiwanese, including 88% of management-level staff. By location, 87% of employees work in Taiwan. The next-largest groups are based in China, the United States, and Japan.

In manufacturing, over 90% of TSMC’s total capacity is in Taiwan—meaning that this small island supports more than 60% of the world’s semiconductor output and over 90% of global advanced-node capacity.

Even as TSMC expands globally, Taiwan remains its largest talent base. It’s not just

...This excerpt is provided for preview purposes. Full article content is available on the original publication.