Rivian's Silicon & Physical AI

Deep Dives

Explore related topics with these Wikipedia articles, rewritten for enjoyable reading:

-

CAN bus

10 min read

The article discusses Rivian's zonal architecture as a departure from legacy automotive systems that use CAN networks. Understanding the Controller Area Network protocol helps readers grasp why traditional automotive electronics architectures are being replaced and what technical debt legacy OEMs face.

-

Cruise (autonomous vehicle)

13 min read

The article references 'GM/Cruise and Ford/Argo' as cautionary examples of why OEMs can't simply acquire their way to autonomy success. The Cruise story illustrates the cultural and organizational challenges of integrating autonomous vehicle startups into legacy automakers.

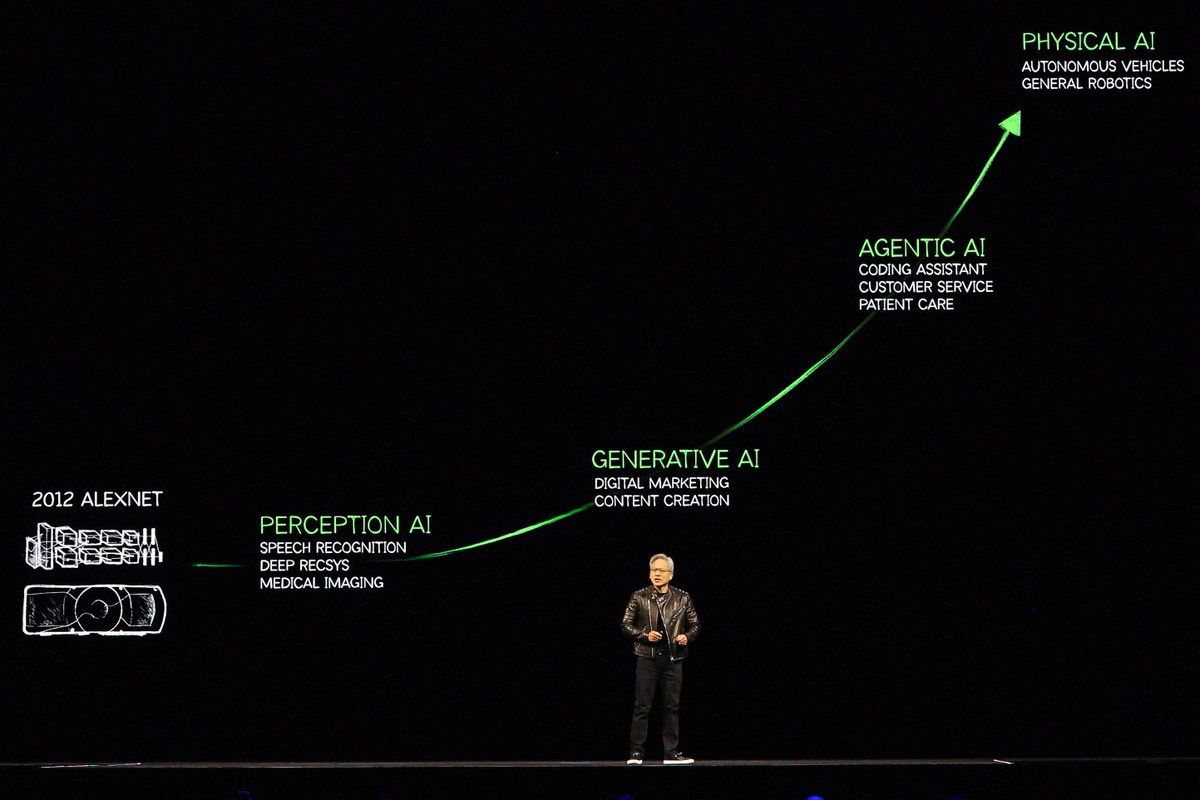

Let’s dive deep into Rivian ahead of its Dec 11 AI & Autonomy Day.

After all, physical AI is the future right?

Rivian might seem to sit outside my usual coverage universe, but I personally love tracking it because the company is exciting from many angles:

🧢 As a Semiconductor analyst: Rivian isn’t like the traditional semis companies I often cover (Nvidia, AMD, Intel, etc), but it’s super interesting in the way that Apple Silicon is super interesting. After all, Apple is a consumer product company that starts with an uncompromising view of the user experience, then designs the silicon and system architecture to support it.

Rivian is analogous: a consumer product company that realized it could only deliver its world-class transportation experience by owning the entire hardware and software stack.

And a lot of silicon content in those battery-powered robots-on-wheels!

A key enabler we’ll dive into is Rivian’s zonal architecture, here’s a nice clip explaining:

RJ: [The legacy OEM approach] is almost the exact opposite of how you would architect a system if you started with a clean sheet. If you put twenty great computer scientists and electronics engineers together, you wouldn’t say, “Let’s build a system of 120 islands of software, all written by different teams, all written to different standards, that communicate through a CAN network, but it’s very hard to make updates to, and the layers of abstraction between the people running the requirements and the people running the software are at a minimum twofold, often three or four layers.”

You would say, “Let’s have the smallest number of computers in the car that make all the decisions.” And so you’d end up with what we now call a zonal architecture. Depending on the size of the vehicle, maybe two computers in a car, one in the front, one in the back. If it’s bigger like an R1, maybe two in the back and one in the front that do all the decisioning across one common software platform running on a standard in-house-built OS.

We built that.

Rivian’s technical story is compelling, but the business story matters just as much and should resonate even with readers who don’t usually follow automotive. We’ll examine how Rivian’s business is differentiated from Tesla, Chinese EV and AV players, and legacy OEMs.

🧢 As an autonomy guy: I come out of the autonomy world where I was

...This excerpt is provided for preview purposes. Full article content is available on the original publication.