Credo AECs

I like to understand companies that win, both from a business strategy angle and a technical differentiation angle.

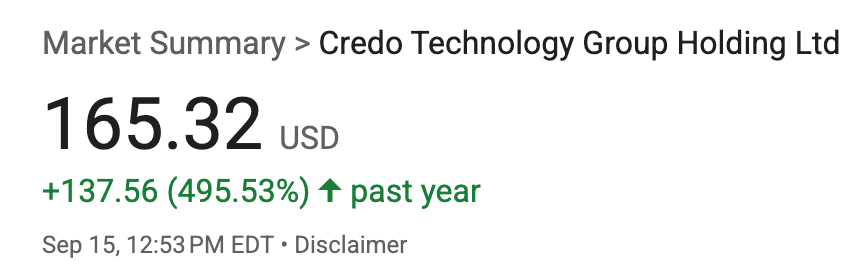

Credo is clearly winning, up 500% since this time last year.

And Active Electrical Cables (AECs) have a lot to do with it.

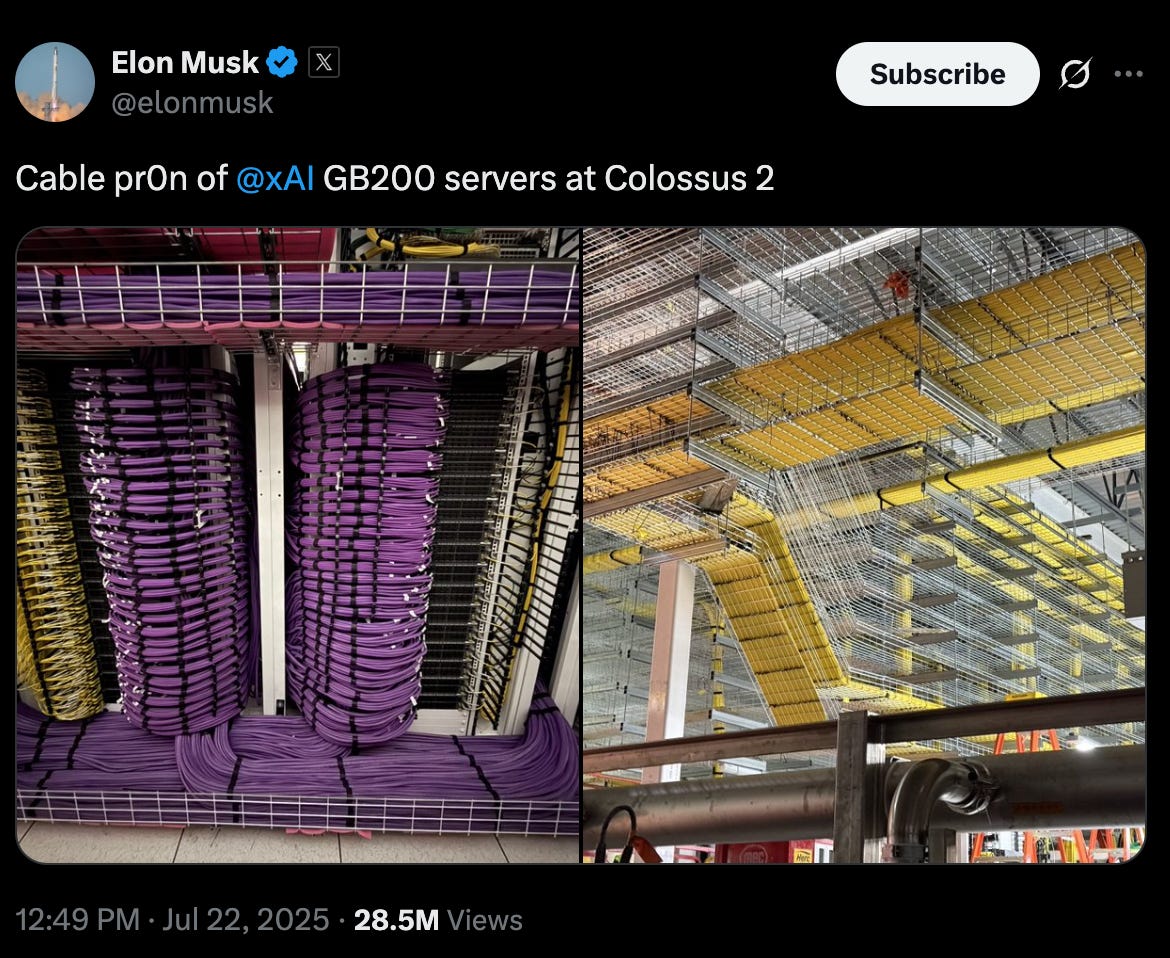

If cables sound boring…well they aren’t to Tony Stark:

Oh, by the way, those purple cables… yep. Credo AECs.

Let’s first cover the technical basics of AECs.

Then for subscribers we’ll go DEEP into the lucrative business of AECs.

The Basics of Active Electrical Cables

Whether it’s Elon wiring up 200K GPUs for xAI’s Colossus or Amazon racking and stacking 2 million Graviton CPUs in the AWS cloud, all that compute still needs to be connected via physical cables. You’ve gotta be able to talk to every machine.

What kind of cables?

Two options: copper and optical.

Copper vs Optical

Copper is simple. Electrical signals travel over a copper wire.

Optical is more complex. Electrical signals must be converted to light signals, which then travel down a fiber and are converted back to electrical at the other end.

Clearly, copper is simpler.

Optical requires an optical transceiver, a small module that houses a semiconductor laser to generate light, modulators to encode the electrical signal onto that light, a fiber to carry the light pulses, and a photodiode receiver to convert them back into electrical form at the other end.

And as you would expect, simple means cheaper. Optical transceivers must be manufactured with extreme precision using exotic materials such as indium phosphide. They are thermally sensitive, generating enough heat that extra cooling and careful thermal design are required. All of that complexity adds cost compared to simple copper wires.

Simple can also mean lower latency. Optical links require extra steps in serialization, encoding, and optical-electrical conversion, which together add nanoseconds.

And as we stated, simple copper cables require less power. Driving an electrical signal over a few meters of copper takes only a fraction of the energy needed to run lasers, modulators, and photodiodes inside an optical module.

What’s maybe less obvious is that simple also means higher reliability. Optical modules have more potential points of failure. Lasers degrade over time, connectors are sensitive to dust and misalignment, and the components are vulnerable to both heat and electrostatic discharge.

Rule of thumb: If you can do it in copper, you should.

By the way, these copper

...This excerpt is provided for preview purposes. Full article content is available on the original publication.